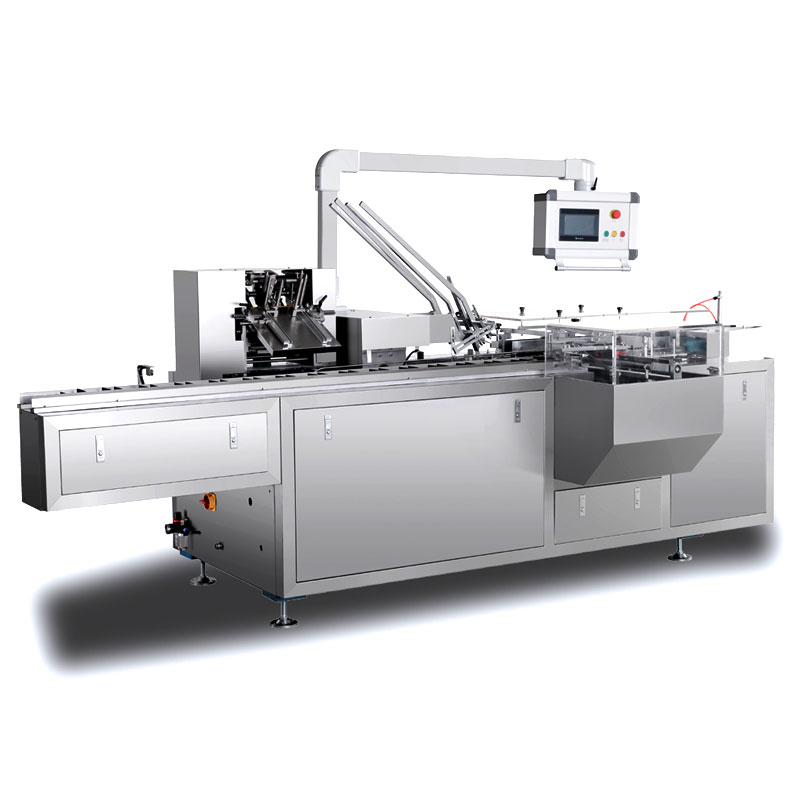

The box packing machine series are beautiful and tightly sealed, which greatly improves the appearance of the product and makes it stand out and attract consumers’ attention. Depending on the sizes of the packing box, our paper box packing machines can produce 50 to 80 boxes per minute. Conducting strict quality control over the production process, Dolly Machinery provides facial tissue box packing machines with consistently high quality.

The multifunctional automatic cartoning box packaging machine the advantages of miniature, light weight, wider application, high efficiency and multi-purpose, etc.

Dolly box packing machine is suitable for cosmetics, medicine, hardware, toys, electronics and other types of products box packaging. The packing machine is a combination of opening, loading, folding and sealing boxes, suitable for many varieties, many specifications of carton packing machine. It can be used alone or combined with other equipment (such as: tube filling machine, labeling machine, cellophane wrapping machine).

The machine can pack all kinds of goods, and it is also suitable for food packaging, cosmetics packaging and other related industries. It has a wide range of use, and according to different use requirements of users, it is suitable for the production of single variety in large quantities, meanwhile, it can meet the needs of user’s many varieties in small batches production.

Advantages

- It can be used alone or connected with other equipment such as cartoning machine for blister and filling machine to match the corresponding machinery and produce together.

- Fully automatic packaging machinery, which can improve production efficiency and delivery time, also reduce labor costs.

- Multi-function boxing operation, all kinds of complex boxing tasks are completed at the same time.

- PLC control system, fault removal display device, easy operation.

- The whole machinery can be moved arbitrarily, which is convenient for adjusting boxes of various specifications.

Applicable Industries

In addition to the previously mentioned products,Dolly custom vertical box packing machine is also widely applied in the following industries for packing lots of items.

- Pharmaceutical: Blisters, oral liquids, ampoules, vials, pharmaceutical granules, plasters, ointments, aerosols, etc.

- Food: Ice cream, egg rolls, bread, coffee sachet, seasoning mix, milk powder, etc.

- Everyday Chemicals: Toothpaste, soap, cosmetics, facial mask, cream, lipstick, mosquito coil, etc.

- Hardware & Electrical Appliances: Bearings, bulbs, switches, sockets, relays, chargers, etc.

- Auto Parts: Spark plugs, filters, piston rings, automotive bulbs, automotive electrical appliances, etc.

- Plastic: Plastic wrap, disposable film gloves, plastic products, etc.

- Stationery & Entertainment: Pens, staplers, staples, inkpad, glue, correction fluid, playing cards, puzzles, toys, handicrafts, etc.

- Personal Care: Paper towels, sanitary napkins, pads, cotton pads, etc.

Main Processing Steps

- First, the carton is fed from the blanking device to the conveyor belt, and the machine transmits the command to the folding machine and the suction box device.

- The box suction device takes out the box in the library and puts it on the moving rail.

- The guide rail clamp fixes the carton, and the push plate pushes the carton open. The two plywood moving with the carton rises from both sides of the guide rail to clamp the sides of the carton from the front to back, so that the carton opens at a right angle and moves forward to the filling area.

- The conveyor belt of the automatic cartoner pack machine transports the materials, and the push rod pushes the materials into the empty boxes in the loading area.

- After the material is pushed into the box by the push rod, the carton will enter the closing station driven by the guide rail. Before closing the box cover, the mechanine will first bend the tongue of the box, and the push plate will push the box cover to bend so that the tongue can be inserted into the box.

Tube Filling Machine

Tube Filling Machine Cartoning Machine

Cartoning Machine Cup Filling Machine

Cup Filling Machine Coffee Capsule Machine

Coffee Capsule Machine Filling Capping Machine

Filling Capping Machine Labeling Machine

Labeling Machine Sachet Packing Machine

Sachet Packing Machine Other Machines

Other Machines