The continuous cartoning machine runs stable and provides easy changeover for different sizes of cartons. It can fold leaflets, open cartons, insert the products and leaflets into cartons, emboss, tuck-in, or hot-melt closures and automatically discharge cartons. The machine is equipped with a series of sensors and automatic protective devices to assure the machine runs safely and effectively.

This machine completes product insertion, leaflet insertion and production batch & expiry date coding in one run. Also equipped are malfunction warnings for fail safe packaging processes. It is labor saving, used to automatically carton a variety of products in various industries, including medical and pharmaceutical, cosmetic, food production, and more.

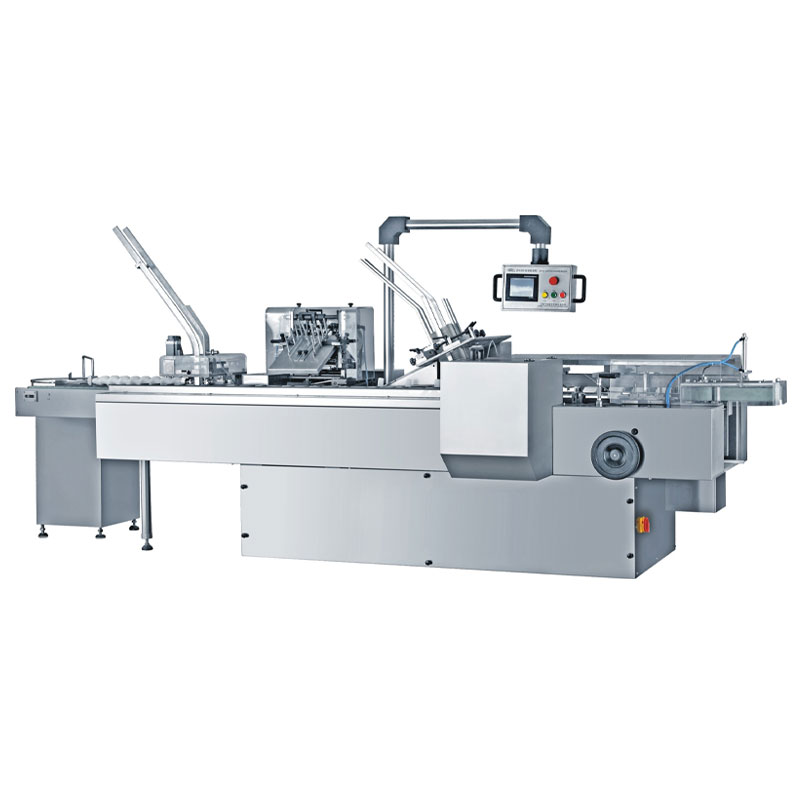

DL-ZH-120 automatic cartoning machine adopting horizontal & continuous motion mechanism, has been designed for multi-function and fully automatic cartoning operation. From carton forming, product insertion, leaflet insertion, coding of control number, manufacturing & expiry dates, to carton closing are all performed in a small space, saving in labor and production cost.

Performance Features

- Packaged Form:It adopts automatic feeding, box opening, box entry, batch number printing, box sealing, waste removal, etc., with compact and reasonable structure.

- Easy to Operate: Servo/stepper motor, touch screen, PLC programmable control system, human-machine interface display operation more clear and simple, high degree of automation, more humanized.

- Wear Protection: The machine frame and the machine board have sufficient strength and stiffness, the frame is equipped with the main drive motor and the clutch brake of the machine, the machine board is equipped with various transmission systems, torque overload protector can realize the main drive motor and the transmission parts in the case of overload, to protect the machine parts from damage.

- Easy to Exchange the Production for Different Products:No need to change the mold , only by adjusting the specifications.

- Automatic photoelectric detection and tracking system is adopted to save the packing material, the box would not be dropped by empty material.

- It can be linked with the production with aluminum-plastic packaging machine, pillow packaging machine,3D packaging machine, bottling line, filling machine, labeling machine, code spraying machine, online weighing machine, other production lines and other equipment.

- Basis on the customer’s demand, the design of automatic feeder and box entry system.

- Basis on the customer’s demand, it can select the hot met glue machine to seal the box, such as the hot melt glue sprayer, or mechanical brush coating.

- High Safety: No products – box wont be dropped, the machine will automatically stop and sound alarm.

- Products – no box/ box UN-forming , the machine will automatically stop and sound alarm.

What Products Are Horizontal Cartoning Machines Used For?

- Pharmaceutical Industry: Medicine Board, MedicineBottle, Oral Liquid, Bagged Granules, Ointment, etc.

- Food Industry: Popsicle, Egg Rolls, Bread, Cookies, Coffee Bag, Seasoning Packets, Milk Powder Bag, etc.

- Daily Chemical Industry:Toothpaste, Soap, Cosmetics, Facial Mask, Cream, Lipstick, Condoms, Mosquito Incense,

- Plastic Industry: Cling Film, Disposable Film Gloves, Plastic Products, etc.

- Entertainment Industry: Pens, Staplers, Glue, Playing Cards, Puzzles, Toys, etc.

Tube Filling Machine

Tube Filling Machine Cartoning Machine

Cartoning Machine Cup Filling Machine

Cup Filling Machine Coffee Capsule Machine

Coffee Capsule Machine Filling Capping Machine

Filling Capping Machine Labeling Machine

Labeling Machine Sachet Packing Machine

Sachet Packing Machine Other Machines

Other Machines