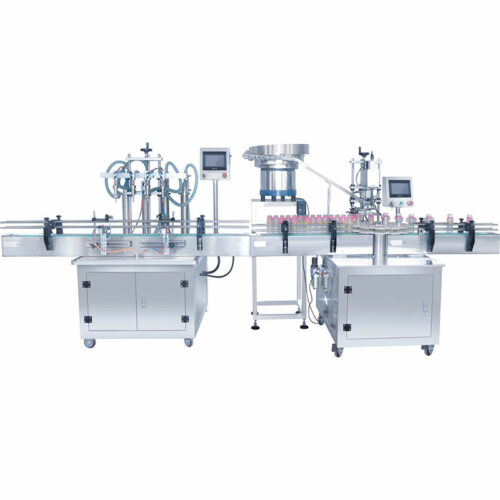

Linear Bottle Filling Machine is an industrial equipment designed to fill bottles with liquid products in a linear fashion. It is commonly used in industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals.

This series of filling machine is suitable for filling different types of liquid and paste products in daily chemical, food, grease, medicine, pesticide and other industries. The piston injection filling and three way one-way valve device has the advantages of high filling accuracy, convenient installation and debugging, simple cleaning and maintenance, and no leakage. The contact part of the material is made of 304 stainless steel (customizable 316L stainless steel).

Dolly’s bottle filling machine is mainly suitable for quantitative filling for fluidity of liquid, viscous liquid such as soy sauce, oil, honey, syrup, sauce, ketchup, shampoo, skin care products, suitable for food, medicine, cosmetics and other industries.

This production line is designed according to advanced filling technology and specially designed for viscosity liquid filling and capping machine. It adopts PLC & touch screen control, the silicone tube is medical grade, the working table is made of high-quality 304 stainless steel, the needles made of 316L stainless steel, which fully meets the requirements of GMP.

The transmission of the machine adopts mechanical transmission, the transmission is accurate and stable, there is no air pollution and there is no error in working between various mechanisms. When working, the noise is low, the loss is low, the work is stable, and the output is stable. It is especially suitable for small and medium batch production, it is the preferred filling equipment for the pharmaceutical industry and hospital preparations.

Features

- HMI settings, intuitive and easy to operate, PLC control, precise loading capacity.

- Frequency control, the production speed arbitrary regulation, and automatic counting.

- Automatic stop function, no bottle will not fill and not torinese.

- Disc positioning filling is stable and reliable.

- High-precision cam indexing control, and positioning precision.

- Fully meet the requirements of GMP.

- Can customize products according to customer bottle samples.

- Adopted piston quantitative, mechanical and electrical, pneumatic in one, electrical and pneumatic components used well-known brands.

- Screen rational design, simple operation.

- Compact structure, beautiful appearance, stable and reliable performance, and easy maintenance.

- Filling accuracy, and adaptability.

Tube Filling Machine

Tube Filling Machine Cartoning Machine

Cartoning Machine Cup Filling Machine

Cup Filling Machine Coffee Capsule Machine

Coffee Capsule Machine Filling Capping Machine

Filling Capping Machine Labeling Machine

Labeling Machine Sachet Packing Machine

Sachet Packing Machine Other Machines

Other Machines